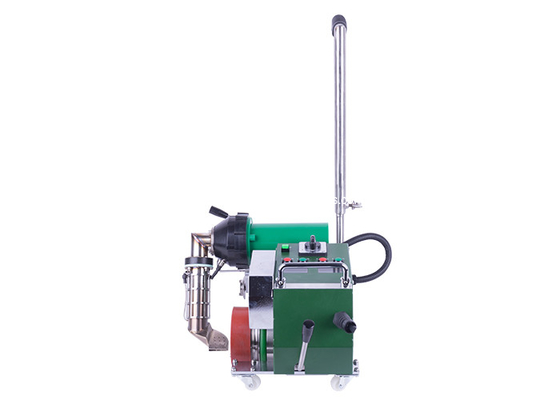

Banner Welder Canvas Tent Tarpaulin Welding Machine Fabric Hot Air Welder

Hot Air Welding Machine Product Feature:

Tarpaulin Welding Heat Machine,Repairing tarps with hot air gun,Automatic tarpaulin welding machine for PE fabric,Banner & Tarpaulin Welder,Hot air welding machine welding TPO-membrane on a roof,PVC Membrane welding machine,40mm PVC Roofing Membrane welder ,Hot air welding machine Roof welding PVC-membrane on a roof,welding of PVC Tarps with overlap machine,PVC Tarpaulin Billboard welding machine,40mm PVC Tarpaulin welding machine,welding machine for thermoplastic tarpaulins billboards and banners,Welding equipment for PVC Profile on a Roof,Automatic welding of PVC Floor covers,TARPAULIN WELDING EQUIPMENT,Hot Air Welding machine for Industrial Fabrics Banner Tarpaulin PVC Welding,PVC banner welding machine for banner joint Tarpaulin welder/ hot seaming machine/Automatic hot air welder,

Hot Air Welding Machine Specification:

| Item no.: |

SWT-MAT2 |

| Voltage: |

220v |

| Frequency: |

50/60 HZ |

| Power: |

3000w |

| Welding Speed: |

1.5-11.6m/min |

| Welding Seam: |

20/30/40mm |

| Heating Temperature: |

20-620℃ |

| Welding Way: |

overlap/hem/rope welding |

| Application: |

Banner, canvas,and other thin material |

| Certification: |

CE |

| Warranty: |

2 years |

Hot Air Welding Machine Introduction:

SWT-NS series geo-membrane welding machine is our new developed products, which can weld geo-membrane of various thickness and are applicable for welding of all thermal-fused material such as LDPE, PVC, HDPE, EVA, PP and so on.Hot Wedge Welder is small, light, high welding efficient. This hot wedge welder is available for welding HDPE, LDPE ,EVA ,PVC, ECB, PP and other hot melt materials.

The control of this series of welding machine adopts PID automatic thermostatic control with high control accuracy and low temperature fluctuation; speed control adopts PWM automatic voltage and speed regulation circuit, driven by DC servo motor, with great output torque and the operating is stable. It can maintain a constant speed on the condition of creeping, vertical creeping and variable road load. Also this series of welding machine is stable in performance despite of external temperature and voltage variation.This series of welding machine is excellent in performance and easy for operating, with high welding speed and good work quality. It is extensively used in engineering projects such as expressways, tunnels, reservoirs, waterproof of construction and so on.

After-sales Service:

We always provide high quality products and workable price for every clients and have won the trust,

enjoy a good reputation in the market.

Machine Quality Guarantee: 24 months.--If any parts broken or does not work under normal operating,

we provide them for free!

FAQ:

Q&A:

1. PAYMENT TERMS

We accept 30% TT deposit and 70% balance payment against photo before delivery or 100% TT in advance.

2. LEAD TIME

Usually, we have plenty of stock for V355 and below, and keep max. 3units for V450 and V630. As to V800 and above, we'll arrange production according to the actual orders.

3. WARRANTY

2 YEARS. During the warranty period, MM-Tech authorized dealer and MM-Tech will totally cover the responsibility to fix the machine; Claim parts usually could be couriered to clients within 3days since receiveing the claim. Express fee will be borned by MM-Tech.

4. CAN YOU DO CUSTOMIZED DESIGN

YES. MM-Tech has its own design and technical team that can undertake OEM and ODM, but there are quantity requirements, please contact our sales consultant for more information, thank you.

5. CAN YOU PROVIDE TRAINING CLASS ?

1. Customers are welcome to come to our factory for 1-2 weeks of training, in addition to air tickets and hotels, MM-Tech can afford meals and local transportation costs.

2. We can also arrange for technical personnel to fly to the customer's local to do on-site training, for a period of 1-2 weeks,customers bear air tickets, hotels, catering, as well as technical training fees, please contact our sales consultant for details.

3.MM-Tech offers online training in English and Spanish, which requires an appointment in advance.

6. HOW COULD BE YOUR DISTRIBUTOR AT LOCAL?

MM-Tech welcomes customers from all over the world to negotiate agency business, but for agents, we have specific requirements, details please contact our sales consultant, thank you!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!